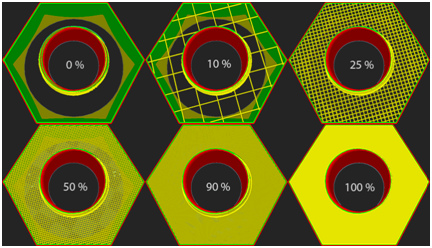

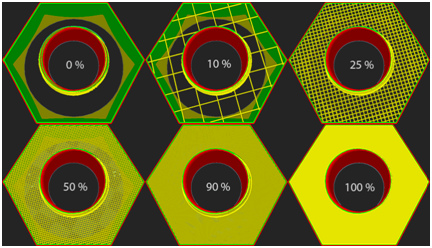

In FDM printing technology, we have the advantage of controlling the amount of material that is filled up inside the volume of the part being printed. Keeping the value at 0 % means that the part is printed as a hollow object, with only an outer shell. Keeping it at 100 % will print a completely solid object, with the print material completely filling up the volume of the part.

A high infill amount will create a denser & a stronger part and which takes longer to build and vice-versa.

Cross-sections of a model of a nut illustrating the variations in the Infill Percentage parameter

Cross-sections of a model of a nut illustrating the variations in the Infill Percentage parameter

We vary the Infill Percentage parameter from project to project, depending on the end-use application of the printed part and also the project budget. For most parts, a value between 20-50 % suffices and very rarely do we need to go higher than that. Please note that it is not necessary for you to mention a value for this parameter along with your 3D printing project details. We will either use our standard values or use our judgement to set values optimum for your project. If you have your custom infill percentage value for your part, you may mention that while

submitting your 3D printing project enquiry to us.

Infill Percentage parameter does not technically apply to 3D printing technologies other than FDM. All other printing technologies will build a completely solid object, by default. Nevertheless, the cost of printing can be reduced by

hollowing the 3D model during the modeling process. Learn more

out here how your 3D printing costs can be reduced through various methods.

Cross-sections of a model of a nut illustrating the variations in the Infill Percentage parameter

Cross-sections of a model of a nut illustrating the variations in the Infill Percentage parameter